To overcome the

problems of low drag on large aircraft with high momentum, the designers have

introduced a variety of drag inducing devices such as;

- Spoilers

- Lift dumpers

- Speed brakers

- Thrust reversals

When landing the

aircraft, for the different landing distances required are based on variables

such as;

- Headwinds

- Aircraft Weight

- Runway length

- Runway Condition (Dry, Wet, Snow, Ice)

- Reverse thrust (Engaged or not)

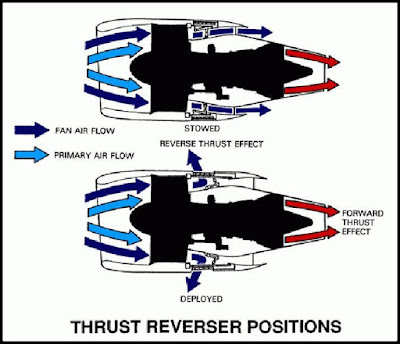

In the thrust

reversals, the airflow is reverse the direction of the exhaust gas stream. The

method of redirecting the flow varies with the size, configuration and the

manufacturer of the engine.

When the runway become

icy or snow covered, to stop the aircraft and additional method should be used.

This is where “Thrust reversals” is used. In this manner, the pilot could

reduce the landing distance of an aircraft.

In high by-pass ratio engines a majority of the thrust is derived from

the fan airflow (bypass air from the fan), the core air from the engine will

exits normal. So changing the direction of the fan airflow would create a net reverse

thrust. Thrust reversals is used to change the direction of the fan airflow.

In Turboprop aircraft reverse thrust action is used by changing the

pitch of the propeller blades. The pitch in which the blade provide reverse

thrust is called the “beta range”. Usually, a hydro-mechanical system is used

to change the blade angle, giving a braking response when activated.

Ideally, the airflow

should be directed in a completely forward direction to gain the complete drag

to stop the aircraft; however, this is not possible, mainly due to aerodynamic

reasons. A discharge angle near 45 degrees is usually chosen, resulting in a

proportionally effective reverse thrust than the thrust of the same engine in

its normal direction.

There are several

methods of obtaining reverse thrust on “Turbo-Jet Engines”:

- Clamshell type deflector doors to reverse the exhaust gas stream.

- Bucket Target system with external type doors (Bucket doors) to reverse the exhaust.

- Fan engines utilize blocker doors to reverse the cold stream airflow system.

1. The

clamshell door system is a

pneumatically operated system. When the pilot activate the reverse thrust

system, the clamshell doors rotate to uncover the ducts and close the inner fan

airflow. Therefore, when the direction of flow is changed, the thrust created

by the fans of the engine will be less. However, this will not affect Normal

engine operation. The thrust created by the primary airflow will be same. Since

80% of the full thrust is generated by the fan airflow. We should only affect

that airflow.

2. The

bucket target system is a

hydraulically actuated system that uses bucket type doors to reverse the hot

gas stream (Exhaust airflow). The thrust reverse doors are actuated by a

conventional hydraulic powered pushrod system. The actuator incorporates a

mechanical lock in the extended position. In the forward thrust mode the bucket

doors form the convergent-divergent final nozzle for the engine.

3. The

cold stream reverse system is

actuated by an air motor. The output is converted into mechanical movement by a

series of flexible drives, gearboxes and screw jacks. During normal operation,

the reverse thrust cascade vanes are covered by the blocker doors. On selection

of reverse thrust, the actuation system folds the blocker doors to blank off

the cold stream final nozzle, thus diverting the airflow through the cascade

vanes.

In passenger aircraft,

reverse thrust is only used when on the ground. There are typically interlocks

in the system that prevent the thrust reversals from deploying if the aircraft

does not sense that it is on the ground. Once the aircraft touches down, the

pilot will deploy the reverse thrust. Buy in military aircraft, thrust

reversals can be used in the air. As it will enable them to perform very steep

descents.

Thrust reversals do not

always have to be operational for an aircraft to fly. The thrust reversals can

also break, in which case they will be mechanically locked to prevent them from

deploying until they can be fixed. Many airlines do not use thrust reverse to

save fuel or maintain a higher runway speed after landing to proceed to the

taxiway if it is near the end of the landing runway that has being used.

Operational

Concerns

Older aircraft with

tail mounted Pratt and Whitney JT-8D series engines such as early DC-9 series,

B-727 and B-737-200’s with low hanging wing engines that used hinged cowls for the

reverse thrust. The pilot can delay deploying it, because with the clearance to

ground there is a high probability for debris entering the engines. Moreover,

if the pilot need to abort the landing to gain the full thrust quickly thrust

reversals should not deployed. Modern airlines

no longer use these types of thrust reverse mechanism.

NOTE-

- The brakes do not become effective until aircraft speed is below 100 knots.

- Thrust Reversals are not getting enough air intake to be effective below 80 knots.

So they are used for

the initial deceleration and then closed once the aircraft slowed down.

Stopping

the A380

This aircraft weighing

in a fully loaded at 1,265,000 pounds. With the braking system, thrust

reversers are the least critical components. Only the two inboard engines

on the A380 are equipped with them. Manufacturers have not install

reversers on two outboard engines to save

the weight and lower the chances that those engines, which will sometime

hang over runway edges, would be damaged by ingesting foreign objects.

With these two

reversers, it do help to slow the A380 but not by much. But these do useful

when there is water or snow on the runway which is slippery. Most modern

airliners use reversers to redirect the airflow. The airflow bypassing the

engine core is blocked from exiting and channeled through an assembly of vanes,

called cascade vanes.

In A380, a pilot can

deploy the thrust reversers only on the ground, and can select a range of

thrust reversal from idle to maximum reverse, until the aircraft has slowed to

below 70 knots, or 80.5 mph (1 knot equals 1.15 mph). At that point, the thrust

reversers must be set at idle reverse.

All airliner engines

now have safeguards built in to keep the thrust reversers from accidentally

deploying during flight.

To stop the A380,

enormous composite Honeywell brakes on

16 of the 20 main landing gear wheels do most of the work. As on most new

airliners, the A380’s brakes are anti-skid.

They work like the anti-skid brakes in your car, responding to extreme pressure

by automatically pulsing to prevent brake lockup and skidding. Almost as

important is the aerodynamic braking

of 16 giant wing top spoilers

swinging skyward to create drag and reduce lift. Reducing lift improves

mechanical braking by putting more weight on the wheels.

-----------------------------------------------------------------------------------

Reference – Extracted from

internet

Comments

Post a Comment